Directional Drilling:

We are proud of providing state of the art equipment from well-known international companies with engineering and manufacturing support. Our directional drilling and measurement services are including:

-

- Downhole motor (Directional and Performance drilling, Sidetracking)

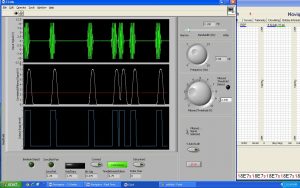

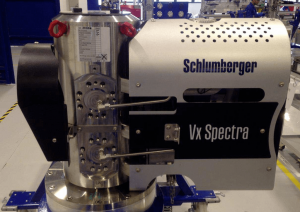

- MWD (Mud pulse and Electromagnetic Telemetry)

- LWD (GR & Resistivity)

- All Directional BHA